A Comprehensive Guide to Selecting the Right Acrylic Flow Meter for Your Needs

2025-07-31

A Comprehensive Guide to Selecting the Right Acrylic Flow Meter for Your Needs

Table of Contents

1. Introduction to Acrylic Flow Meters

2. Understanding the Importance of Flow Measurement

3. Types of Acrylic Flow Meters

3.1 Positive Displacement Flow Meters

3.2 Turbine Flow Meters

3.3 Magnetic Flow Meters

3.4 Ultrasonic Flow Meters

4. Key Features to Consider When Selecting an Ac

A Comprehensive Guide to Selecting the Right Acrylic Flow Meter for Your Needs

Table of Contents

1. Introduction to Acrylic Flow Meters

2. Understanding the Importance of Flow Measurement

3. Types of Acrylic Flow Meters

3.1 Positive Displacement Flow Meters

3.2 Turbine Flow Meters

3.3 Magnetic Flow Meters

3.4 Ultrasonic Flow Meters

4. Key Features to Consider When Selecting an Acrylic Flow Meter

4.1 Accuracy and Precision

4.2 Flow Range and Capacity

4.3 Pressure and Temperature Ratings

4.4 Material Compatibility

5. Installation Guidelines for Acrylic Flow Meters

6. Maintenance Best Practices for Long-Lasting Performance

7. Common Applications of Acrylic Flow Meters

8. Frequently Asked Questions (FAQs)

9. Conclusion

1. Introduction to Acrylic Flow Meters

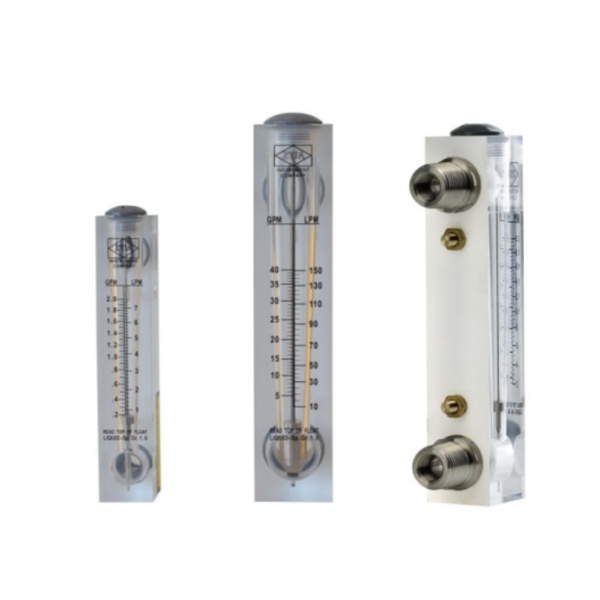

Acrylic flow meters play a crucial role in various industries, including chemical processing, water treatment, and HVAC systems. These instruments are designed to provide accurate measurements of fluid flow, whether it be gas or liquid. Due to their transparent construction, acrylic flow meters offer a unique advantage, allowing users to visually inspect the fluid flow while monitoring its rate.

Choosing the right acrylic flow meter can significantly impact operational efficiency. This comprehensive guide aims to equip you with the necessary knowledge to make an informed decision, ensuring that your selected flow meter meets your specific needs.

2. Understanding the Importance of Flow Measurement

Flow measurement is a vital process in numerous applications. Accurate flow readings allow businesses to monitor system performance, optimize resource usage, and ensure compliance with regulatory standards. In industries such as pharmaceuticals and food processing, precise flow measurement can prevent costly errors and enhance product quality.

Incorporating an acrylic flow meter into your operations enables real-time monitoring, which can lead to improved decision-making and reduced downtime. By understanding flow measurement's significance, you can appreciate the value of selecting the right instrument for your applications.

3. Types of Acrylic Flow Meters

When considering an acrylic flow meter, it's essential to understand the various types available:

3.1 Positive Displacement Flow Meters

Positive displacement flow meters measure fluid flow by capturing a specific volume of liquid and allowing it to displace a mechanical element. These meters are known for their accuracy and are ideal for low-flow applications. They are particularly effective with viscous fluids.

3.2 Turbine Flow Meters

Turbine flow meters utilize a rotor that spins in response to fluid flow. The rotational speed correlates with the flow rate, making these meters suitable for applications with clean, low-viscosity fluids. They offer a good balance between accuracy and cost-effectiveness.

3.3 Magnetic Flow Meters

Magnetic flow meters operate on the principle of electromagnetic induction. They are suitable for measuring conductive liquids and provide high accuracy across a wide flow range. These meters are commonly used in water treatment and chemical processing industries.

3.4 Ultrasonic Flow Meters

Ultrasonic flow meters use sound waves to measure fluid flow. They are non-invasive and can be installed on existing pipelines, making them versatile and easy to maintain. These meters are ideal for various applications, including wastewater treatment and HVAC systems.

4. Key Features to Consider When Selecting an Acrylic Flow Meter

Selecting the right acrylic flow meter involves considering several critical features:

4.1 Accuracy and Precision

Accuracy is paramount when it comes to flow measurement. Look for flow meters with specifications that meet your requirements. High-quality acrylic flow meters should offer a low margin of error to ensure reliable data.

4.2 Flow Range and Capacity

Different applications require different flow ranges. It's crucial to select a flow meter that can measure the specific flow rates relevant to your operations. Ensure that the meter’s capacity aligns with your maximum expected flow.

4.3 Pressure and Temperature Ratings

Understanding the operating conditions of your application is essential. Ensure that the acrylic flow meter can withstand the pressure and temperature extremes of your fluid. This consideration will help avoid equipment failure and ensure longevity.

4.4 Material Compatibility

Acrylic flow meters are often selected for their transparency and ease of use. However, it's essential to ensure that the meter's materials are compatible with the fluids being measured, preventing chemical reactions that could compromise functionality.

5. Installation Guidelines for Acrylic Flow Meters

Proper installation of acrylic flow meters is crucial for optimal performance. Here are key guidelines to follow:

1. **Select a Suitable Location:** Choose an installation site that allows for unobstructed fluid flow and easy access for maintenance.

2. **Follow Manufacturers’ Instructions:** Adhere to the installation guidelines provided by the manufacturer to ensure proper functioning.

3. **Ensure Correct Orientation:** Install the flow meter in the correct orientation as specified, typically horizontal or vertical, to maintain accuracy.

4. **Utilize Appropriate Fittings:** Use compatible fittings to prevent leaks and ensure a secure connection between the meter and the pipeline.

5. **Calibrate After Installation:** Once installed, calibrate the flow meter according to the manufacturer's recommendations to ensure accurate measurements from the outset.

6. Maintenance Best Practices for Long-Lasting Performance

Regular maintenance is key to ensuring the longevity and efficiency of your acrylic flow meter. Here are some best practices:

1. **Routine Inspections:** Periodically inspect the flow meter for signs of wear, damage, or buildup that could affect performance.

2. **Clean the Meter:** Depending on the fluid being measured, it may be necessary to clean the flow meter regularly to prevent blockages or inaccuracies.

3. **Check Calibration:** Regularly verify the calibration of the flow meter to maintain measurement accuracy over time.

4. **Monitor Performance:** Keep an eye on flow readings and compare them with expected results. Any significant discrepancies should prompt an inspection.

5. **Follow Manufacturer Guidelines:** Always refer to the manufacturer's maintenance guidelines for specific recommendations tailored to your model.

7. Common Applications of Acrylic Flow Meters

Acrylic flow meters are versatile instruments used in various applications, including:

- **Water Treatment:** Monitoring water flow in treatment plants to ensure optimal processes.

- **Chemical Processing:** Precise measurement of chemical flow rates in production and mixing operations.

- **HVAC Systems:** Maintaining airflow and ensuring efficiency in heating and cooling systems.

- **Food and Beverage Industry:** Ensuring accurate ingredient measurement for quality control in production.

- **Aquarium and Aquaculture:** Monitoring water flow rates to maintain healthy environments for aquatic life.

8. Frequently Asked Questions (FAQs)

**Q1: What is an acrylic flow meter?**

An acrylic flow meter is a device used to measure the flow rate of fluids, typically offering a transparent design for visual inspection and monitoring.

**Q2: How do I choose the right flow meter for my application?**

Consider factors such as accuracy, flow range, material compatibility, and installation requirements to select the best flow meter for your needs.

**Q3: Are acrylic flow meters suitable for high-pressure applications?**

Acrylic flow meters are generally not recommended for high-pressure applications due to the limitations of the material. Always check the specifications for pressure ratings.

**Q4: Can I install an acrylic flow meter myself?**

Yes, provided you follow the manufacturer’s installation instructions and consider your familiarity with plumbing and flow measurement devices.

**Q5: How often should I calibrate my acrylic flow meter?**

Calibration frequency depends on the application and usage. Regular checks are advisable to maintain measurement accuracy.

9. Conclusion

Selecting the right acrylic flow meter is essential for accurate fluid measurement in various applications. By understanding the different types, key features, and maintenance practices, you can make an informed choice that enhances your operational efficiency. Investing time in proper installation and regular maintenance will ensure the longevity and reliability of your acrylic flow meter. With the insights provided in this comprehensive guide, you are now equipped to choose the perfect acrylic flow meter for your specific needs, leading to improved performance and productivity in your operations.

Acrylic Flow Meter

RELATED NEWS

A Comprehensive Guide to Selecting the Right Acrylic Flow Meter for Your Needs

2025-07-31

A Comprehensive Guide to Selecting the Right Acrylic Flow Meter for Your Needs

Table of Contents

1. Introduction to Acrylic Flow Meters

2. Understanding the Importance of Flow Measurement

3. Types of Acrylic Flow Meters

3.1 Positive Displacement Flow Meters

3.2 Turbine Flow Meters

3.3 Magnetic Flow Meters

3.4 Ultrasonic Flow Meters

4. Key Features to Consider When Selecting an Ac

Understanding Durable Plastic Tube Type Flowmeters: Key Insights for Professionals

2025-07-24

Durable plastic tube type flowmeters are widely utilized in various industries for measuring the flow rates of liquids and gases. Their design incorporates a transparent or semi-transparent plastic tube, allowing users to visually monitor the flow of the medium. This type of flowmeter is particularly advantageous due to its lightweight nature, corrosion resistance, and cost-effectiveness, making i

Choosing the Right Panel Type Flowmeter for Your Application: A Comprehensive Guide

2025-07-17

Choosing the Right Panel Type Flowmeter for Your Application

Table of Contents

1. Understanding Flowmeters: A Brief Overview

2. Importance of Selecting the Right Flowmeter

3. Types of Panel Type Flowmeters

3.1. Electromagnetic Flowmeters

3.2. Ultrasonic Flowmeters

3.3. Coriolis Flowmeters

3.4. Turbine Flowmeters

3.5. Positive Displacement Flowmeters

4. Key Considerations When Choosing a Flowmeter