Choosing the Right Panel Type Flowmeter for Your Application: A Comprehensive Guide

2025-07-17

Choosing the Right Panel Type Flowmeter for Your Application

Table of Contents

1. Understanding Flowmeters: A Brief Overview

2. Importance of Selecting the Right Flowmeter

3. Types of Panel Type Flowmeters

3.1. Electromagnetic Flowmeters

3.2. Ultrasonic Flowmeters

3.3. Coriolis Flowmeters

3.4. Turbine Flowmeters

3.5. Positive Displacement Flowmeters

4. Key Considerations When Choosing a Flowmeter

Choosing the Right Panel Type Flowmeter for Your Application

Table of Contents

1. Understanding Flowmeters: A Brief Overview

2. Importance of Selecting the Right Flowmeter

3. Types of Panel Type Flowmeters

3.1. Electromagnetic Flowmeters

3.2. Ultrasonic Flowmeters

3.3. Coriolis Flowmeters

3.4. Turbine Flowmeters

3.5. Positive Displacement Flowmeters

4. Key Considerations When Choosing a Flowmeter

4.1. Application Requirements

4.2. Fluid Characteristics

4.3. Measurement Range and Accuracy

5. Installation and Maintenance Considerations

5.1. Installation Guidelines

5.2. Maintenance Best Practices

6. Common Applications for Panel Type Flowmeters

7. Frequently Asked Questions (FAQs)

8. Conclusion

1. Understanding Flowmeters: A Brief Overview

Flowmeters are instruments designed to measure the flow rate of liquids and gases in various applications. The choice of flowmeter impacts system efficiency, operational effectiveness, and overall accuracy in measurement. To ensure optimal performance, it is crucial to understand the fundamental principles of how flowmeters operate and the various technologies available in the market.

2. Importance of Selecting the Right Flowmeter

Selecting the right flowmeter is essential for several reasons. An appropriate flowmeter ensures accurate measurements, enhances process control, and improves operational efficiency. Additionally, the correct choice can lead to significant cost savings in terms of maintenance and energy consumption. Failing to choose the right type may result in inaccurate readings, equipment damage, and increased downtime.

3. Types of Panel Type Flowmeters

There is a wide variety of panel type flowmeters, each suited for specific applications and fluid types. Understanding these options can significantly impact your selection process.

3.1. Electromagnetic Flowmeters

Electromagnetic flowmeters operate based on Faraday's law of electromagnetic induction. They are particularly effective for measuring the flow of conductive fluids, such as water and slurries. These flowmeters are often utilized in wastewater treatment and chemical processing, where accuracy and reliability are paramount.

3.2. Ultrasonic Flowmeters

Ultrasonic flowmeters use high-frequency sound waves to measure fluid velocity. They are non-intrusive and suitable for a variety of applications, including clean liquids and gases. Their ability to measure without obstructing flow makes them ideal for sensitive environments, such as food and beverage processing.

3.3. Coriolis Flowmeters

Coriolis flowmeters measure mass flow and density by utilizing the Coriolis effect. They are highly accurate and are often employed in critical applications, such as in the pharmaceutical and petrochemical industries, where precision is crucial.

3.4. Turbine Flowmeters

Turbine flowmeters measure the flow rate by spinning a turbine rotor driven by the fluid flow. They are widely used in various applications, including oil and gas, due to their reliability and relatively low cost. However, they may not perform well with non-laminar flow or highly viscous fluids.

3.5. Positive Displacement Flowmeters

Positive displacement flowmeters measure fluid volume by trapping a fixed amount of fluid and counting the number of times this volume is displaced. They are known for their accuracy and are commonly used in applications requiring precise measurement of low flow rates, like in fuel dispensing systems.

4. Key Considerations When Choosing a Flowmeter

When selecting a panel type flowmeter, several factors must be assessed to ensure optimal performance.

4.1. Application Requirements

Understanding the specific needs of your application is critical. Consider the type of fluid being measured, the required accuracy, and the measurement range. Different industries may demand distinct specifications, so tailoring your choice to your specific needs is vital.

4.2. Fluid Characteristics

The nature of the fluid—such as viscosity, temperature, and conductivity—plays a significant role in determining the most suitable flowmeter. For example, viscous fluids may require a flowmeter designed to handle higher pressure drops.

4.3. Measurement Range and Accuracy

Define the expected flow range for your application. Flowmeters have different operational ranges and levels of accuracy. Evaluating these parameters against your requirements will help in selecting the most appropriate option.

5. Installation and Maintenance Considerations

Proper installation and regular maintenance are crucial for maintaining flowmeter accuracy and functionality.

5.1. Installation Guidelines

Follow manufacturer guidelines during installation to ensure optimal performance. The location of installation should minimize disturbances, such as bends and valves, that may affect flow readings. Proper alignment and securing of the flowmeter are also important to avoid inaccuracies.

5.2. Maintenance Best Practices

Regular maintenance ensures the longevity of your flowmeter. It’s essential to check for leaks, verify calibration, and clean the device as needed. Following a preventive maintenance schedule can help avoid unexpected failures and enhance measurement reliability.

6. Common Applications for Panel Type Flowmeters

Panel type flowmeters are utilized across various industries, including:

- **Water and Wastewater Management:** Monitoring flow rates in treatment plants.

- **Chemical Processing:** Ensuring accurate delivery of chemicals in production processes.

- **Oil and Gas:** Measuring the flow of crude oil and natural gas.

- **Food and Beverage:** Monitoring ingredients in production lines.

- **Pharmaceuticals:** Ensuring the accuracy of ingredient measurements in drug manufacturing.

7. Frequently Asked Questions (FAQs)

7.1. What is the most accurate type of flowmeter?

Coriolis flowmeters are known for their high accuracy, especially in applications requiring precise mass flow measurement.

7.2. Can flowmeters handle varying fluid characteristics?

Yes, many modern flowmeters can accommodate changes in fluid characteristics, but it’s essential to choose one that is specifically designed for such conditions.

7.3. How often should flowmeters be calibrated?

Calibration frequencies depend on the application and the specific flowmeter. Regular checks—typically at least once a year—are recommended to maintain accuracy.

7.4. What are the risks of using an incorrect flowmeter?

Using an incorrect flowmeter can lead to inaccurate measurements, which may result in operational inefficiencies, safety hazards, and increased costs.

7.5. Are ultrasonic flowmeters suitable for all types of fluids?

While ultrasonic flowmeters are versatile, they work best with clean, non-opaque liquids. They may not be effective for slurries or highly viscous fluids.

8. Conclusion

Choosing the right panel type flowmeter is a critical decision that can significantly affect your operational efficiency and accuracy. By understanding the types of flowmeters available, the key considerations for selection, and the importance of proper installation and maintenance, you can make informed choices that cater to your specific application needs. Investing time and resources into thorough research and consideration will ultimately pay dividends in your measurement processes, leading to enhanced accuracy and performance in your operations. Ensure your decision is based on a clear understanding of your requirements, and leverage the insights from this guide to optimize your fluid measurement solutions.

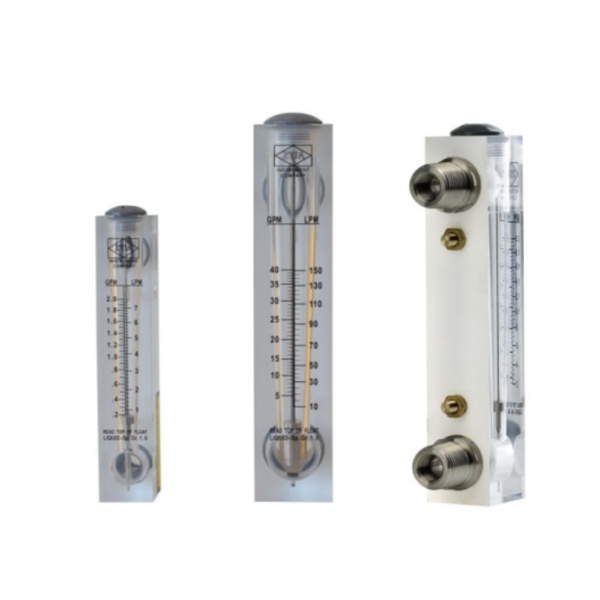

Flowmeter-panel type

RELATED NEWS

Choosing the Right Panel Type Flowmeter for Your Application: A Comprehensive Guide

2025-07-17

Choosing the Right Panel Type Flowmeter for Your Application

Table of Contents

1. Understanding Flowmeters: A Brief Overview

2. Importance of Selecting the Right Flowmeter

3. Types of Panel Type Flowmeters

3.1. Electromagnetic Flowmeters

3.2. Ultrasonic Flowmeters

3.3. Coriolis Flowmeters

3.4. Turbine Flowmeters

3.5. Positive Displacement Flowmeters

4. Key Considerations When Choosing a Flowmeter

Exploring the Role of Internet of Things Instruments in the Healthcare Sector

2025-07-10

The Internet of Things (IoT) instruments are revolutionizing various sectors, and the healthcare industry is no exception. These devices enable the connectivity and communication of medical equipment and patient monitoring systems, facilitating a more integrated and efficient healthcare delivery model. In the realm of medical devices, IoT instruments encompass a wide array of tools, from wearable

2025-07-03

Enhancing Water Quality Assessment: The Role of Electromagnetic Flow Meters in Improving Efficiency and Accuracy

Table of Contents

1. Introduction to Water Quality Assessment

2. Importance of Accurate Water Quality Assessment

3. Understanding Electromagnetic Flow Meters

4. How Electromagnetic Flow Meters Work

5. Benefits of Using Electromagnetic Flow Meters for Water Quality A