Top Benefits of Using Acrylic Flow Meters in Industrial Applications

2025-04-24

Top Benefits of Using Acrylic Flow Meters in Industrial Applications

Table of Contents

1. Introduction to Acrylic Flow Meters

2. Understanding Acrylic Flow Meters

3. Precision and Accuracy in Measurements

4. Cost-Effectiveness and Durability

5. Ease of Installation and Maintenance

6. Versatility in Industrial Applications

7. Safety Standards and Compliance

8. The F

Top Benefits of Using Acrylic Flow Meters in Industrial Applications

Table of Contents

- 1. Introduction to Acrylic Flow Meters

- 2. Understanding Acrylic Flow Meters

- 3. Precision and Accuracy in Measurements

- 4. Cost-Effectiveness and Durability

- 5. Ease of Installation and Maintenance

- 6. Versatility in Industrial Applications

- 7. Safety Standards and Compliance

- 8. The Future of Acrylic Flow Meters in Industry

- 9. Frequently Asked Questions (FAQs)

- 10. Conclusion

1. Introduction to Acrylic Flow Meters

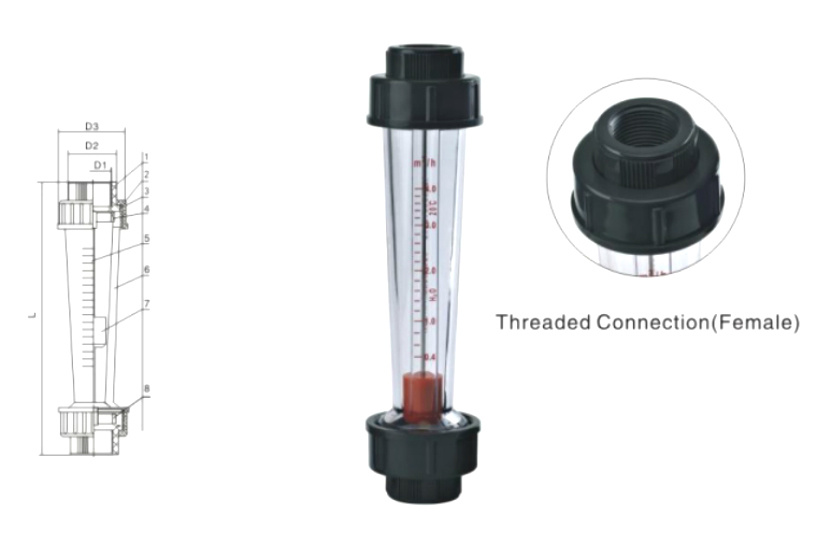

Acrylic flow meters are pivotal in measuring the flow rates of liquids and gases in various industrial applications. These instruments, made from high-quality acrylic materials, provide a clear view of the flow, allowing operators to monitor processes efficiently. With the increasing complexities of industrial operations, utilizing advanced metering technologies is crucial for optimizing performance and maintaining safety standards.

2. Understanding Acrylic Flow Meters

Acrylic flow meters operate on different principles, including variable area, turbine, and electromagnetic methods. The fundamental advantage of acrylic construction lies in its transparency, which allows for easy visual monitoring. Acrylic flow meters are ideal for applications requiring precise flow measurements, such as chemical processing, food and beverage production, and water treatment facilities.

2.1 Types of Acrylic Flow Meters

Different types of acrylic flow meters serve various industry needs. The most common include:

- **Variable Area Flow Meters**: Measure flow by allowing the fluid to pass through a tapered tube, where the flow rate is indicated by the position of a float.

- **Turbine Flow Meters**: Use a rotor that spins as the fluid flows through it, translating the rotational speed into flow rate measurements.

- **Electromagnetic Flow Meters**: Utilize the principle of electromagnetic induction to measure the flow of conductive liquids.

3. Precision and Accuracy in Measurements

One of the most significant advantages of acrylic flow meters is their high precision and accuracy. These meters can measure flow rates with minimal deviation, providing reliable data critical for process control. Precise measurements are vital in industries where even slight variances can lead to inefficiencies, product quality issues, or safety concerns.

3.1 Calibration for Enhanced Accuracy

Regular calibration of acrylic flow meters ensures sustained accuracy over time. Industrial applications benefit from this feature, as it guarantees that the flow meters remain within specified tolerances, which is essential for regulatory compliance and optimal operational efficiency.

4. Cost-Effectiveness and Durability

Acrylic flow meters are often more cost-effective than their glass or metal counterparts. The acrylic material is generally less expensive while offering comparable performance in many applications. Additionally, acrylic flow meters are lightweight and resistant to corrosion, resulting in lower replacement and maintenance costs over their lifespan.

4.1 Long-Lasting Performance

Acrylic flow meters can withstand a wide range of temperatures and pressures, making them suitable for various environments. Their durability reduces the frequency of replacements, allowing companies to allocate resources to other critical areas.

5. Ease of Installation and Maintenance

Installing acrylic flow meters is straightforward due to their lightweight design and the availability of various connection types. Most models come with user-friendly instructions, facilitating quick setup. Furthermore, acrylic flow meters require minimal maintenance, as their construction allows for easy cleaning and inspection.

5.1 User-Friendly Design

Many acrylic flow meters feature intuitive designs that enable operators to perform routine checks without extensive training. This aspect significantly reduces downtime and contributes to overall operational efficiency.

6. Versatility in Industrial Applications

Acrylic flow meters can be utilized across numerous sectors, including pharmaceuticals, food processing, HVAC systems, and chemical manufacturing. Their adaptability makes them suitable for measuring various fluids, from clear liquids to viscous substances.

6.1 Specific Industry Applications

- **Pharmaceuticals**: Accurate measurement of liquid medications is crucial for dosing and compliance.

- **Food Processing**: Ensures consistent flow rates for ingredients, maintaining product quality and safety.

- **Water Treatment**: Monitors flow rates in treatment processes to ensure effective purification.

7. Safety Standards and Compliance

Safety is paramount in industrial environments. Acrylic flow meters comply with various industry standards, ensuring they meet the necessary safety requirements. Their transparent design allows for easy visibility, enabling rapid identification of flow issues that may pose safety risks.

7.1 Compliance with Regulatory Bodies

Regulatory bodies often require precise measurements and documentation of flow rates. Acrylic flow meters provide the necessary accuracy and reliability to meet these demands, ensuring compliance and avoiding potential fines.

8. The Future of Acrylic Flow Meters in Industry

As technology continues to advance, acrylic flow meters are evolving too. Innovations such as IoT integration, enhanced data analytics, and smart sensors are paving the way for more efficient monitoring and control systems. The future promises even greater accuracy and real-time data collection, further solidifying acrylic flow meters' role in industrial applications.

8.1 Technological Advancements

With ongoing research and development, manufacturers are enhancing acrylic flow meters' functionalities. These advancements will enable industries to harness data-driven insights, optimizing processes and reducing costs significantly.

9. Frequently Asked Questions (FAQs)

9.1 What is an acrylic flow meter?

An acrylic flow meter is a device used to measure the flow rate of liquids and gases, made primarily from acrylic materials, which provide transparency for easy monitoring.

9.2 What are the advantages of using acrylic flow meters?

Acrylic flow meters offer high precision, cost-effectiveness, durability, ease of installation, and versatility across various industrial applications.

9.3 Are acrylic flow meters suitable for high-pressure applications?

While acrylic flow meters can handle various pressures, it is essential to select a model specifically designed for high-pressure environments to ensure safety and accuracy.

9.4 How often should acrylic flow meters be calibrated?

Calibration frequency depends on usage, but it is generally recommended to calibrate acrylic flow meters at least once a year or before significant operational changes.

9.5 Can acrylic flow meters be used in hazardous environments?

Certain acrylic flow meters are designed to meet safety standards for hazardous environments. It is crucial to verify the specifications and compliance certifications before use.

10. Conclusion

In summary, acrylic flow meters are invaluable instruments in industrial applications, offering a combination of precision, cost-effectiveness, and versatility. Their transparent design enhances operational visibility, while their durability ensures long-lasting performance. As industries continue to evolve, adopting innovative flow measurement technologies like acrylic flow meters will be paramount for optimizing operations and ensuring safety. By understanding the benefits and functionalities of these essential tools, businesses can make informed decisions that drive efficiency and compliance in their processes.

Acrylic Flow Meter

RELATED NEWS

Understanding Vorex Flow Meters: Innovations in Fluid Measurement

2025-05-01

In the realm of fluid measurement, Vorex flow meters stand out as a versatile and innovative solution for professionals seeking precision and reliability. These instruments are designed to measure the flow rate of liquids and gases in various industrial applications, including chemical processing, water treatment, and HVAC systems. Understanding how Vorex flow meters operate and their benefits can

Top Benefits of Using Acrylic Flow Meters in Industrial Applications

2025-04-24

Top Benefits of Using Acrylic Flow Meters in Industrial Applications

Table of Contents

1. Introduction to Acrylic Flow Meters

2. Understanding Acrylic Flow Meters

3. Precision and Accuracy in Measurements

4. Cost-Effectiveness and Durability

5. Ease of Installation and Maintenance

6. Versatility in Industrial Applications

7. Safety Standards and Compliance

8. The F

Understanding Durable Plastic Tube Type Flowmeters: Key Insights and Applications

2025-04-17

Durable plastic tube type flowmeters are instruments designed to measure the flow rates of liquids and gases with precision and reliability. Their construction typically features a transparent plastic tube that allows for easy visibility of the flowing medium, making them popular in various applications. The key to their effectiveness lies in their ability to provide accurate measurements while be