How Panel Type Flowmeters Enhance Gas Flow Measurement Accuracy: The Ultimate Guide

2025-04-10

How Panel Type Flowmeters Enhance Gas Flow Measurement Accuracy

In industrial processes, accurate gas flow measurement is critical for ensuring efficiency, safety, and compliance with regulations. Panel type flowmeters have emerged as a leading solution for gas flow measurement, providing enhanced accuracy and reliability. This article explores the various aspects of panel type flowmeters, their benefits, applications, and maintenance practices that contribute to their effectiveness in measuring gas flow.

Table of Contents

- Introduction to Panel Type Flowmeters

- Understanding How Panel Type Flowmeters Work

- Advantages of Using Panel Type Flowmeters for Gas Measurement

- Applications of Panel Type Flowmeters in Various Industries

- Achieving Accurate Gas Flow Measurement with Panel Type Flowmeters

- Maintenance Tips for Panel Type Flowmeters

- Challenges in Gas Flow Measurement and How to Overcome Them

- Future Trends in Flow Measurement Technology

- Frequently Asked Questions

- Conclusion

Introduction to Panel Type Flowmeters

Panel type flowmeters are measuring instruments designed to monitor the flow of gases and liquids in various applications. They are primarily used in industries such as oil and gas, chemical manufacturing, water treatment, and HVAC systems. With advancements in technology, these flowmeters have become increasingly sophisticated, offering improved accuracy and ease of use.

What Are Panel Type Flowmeters?

Panel type flowmeters consist of a flow sensing element installed within a panel, providing a user-friendly interface for monitoring flow rates. These devices can measure different parameters, including flow velocity, volume, and pressure, making them versatile tools for various industrial applications.

Understanding How Panel Type Flowmeters Work

The functionality of panel type flowmeters relies on several underlying principles of fluid mechanics and sensor technology. By converting the flow of gas into a measurable signal, these instruments provide real-time data that can be used for analysis and control.

Flow Sensing Technologies

Panel type flowmeters employ various flow sensing technologies, including:

- Thermal Mass Flow Measurement: This method uses temperature sensors to measure the heat transfer in the gas flow, providing accurate mass flow readings.

- Ultrasonic Flow Measurement: This technique employs ultrasonic waves to measure the flow velocity of gas, offering high accuracy and reliability.

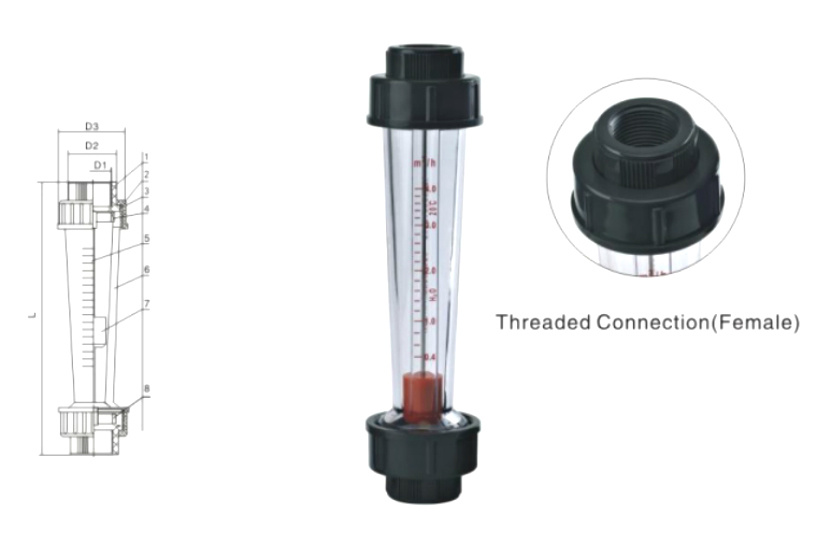

- Variable Area Flow Measurement: Also known as rotameters, this type utilizes a float that rises and falls with changing flow rates, providing a visual indication of flow.

Advantages of Using Panel Type Flowmeters for Gas Measurement

The adoption of panel type flowmeters in gas measurement applications offers numerous advantages that contribute to their popularity in various industries.

Enhanced Accuracy and Reliability

Panel type flowmeters are designed to deliver high accuracy in gas flow measurement. With advanced sensing technologies, they can minimize errors caused by external factors, ensuring reliable data for process control.

User-Friendly Interface

These flowmeters come with intuitive displays and controls, simplifying the monitoring process for operators. Users can easily read measurements and adjust parameters as needed, enhancing overall efficiency.

Versatility in Application

Panel type flowmeters are suitable for a wide range of gases, including corrosive and hazardous gases. This versatility makes them ideal for diverse industrial settings, from chemical plants to HVAC systems.

Applications of Panel Type Flowmeters in Various Industries

Panel type flowmeters find applications across multiple sectors due to their accuracy and reliability. Some of the key industries utilizing these devices include:

Oil and Gas Industry

In the oil and gas sector, accurate flow measurement is vital for operational efficiency and regulatory compliance. Panel type flowmeters are used to monitor gas flow during extraction, processing, and transportation.

Chemical Manufacturing

Chemical manufacturers rely on precise gas flow measurement to ensure product quality and safety. Panel type flowmeters help monitor reactants and by-products in various chemical processes.

Water Treatment

Water treatment facilities use panel type flowmeters to measure and control the flow of gases like chlorine and ozone, essential for water purification processes.

HVAC Systems

In HVAC systems, these flowmeters help regulate airflow and optimize energy consumption, contributing to efficient heating and cooling processes.

Achieving Accurate Gas Flow Measurement with Panel Type Flowmeters

To maximize the accuracy of gas flow measurement with panel type flowmeters, several best practices should be followed:

Calibration and Validation

Regular calibration of flowmeters ensures that they provide accurate measurements over time. Validation against known standards is also crucial for maintaining reliability.

Installation Best Practices

Proper installation is essential for accurate measurements. Ensure that the flowmeter is placed in a straight section of the pipeline, free from obstructions and disturbances.

Environmental Considerations

Environmental factors such as temperature, pressure, and humidity can affect flow measurement accuracy. Operators should account for these variables during measurement and calibration.

Maintenance Tips for Panel Type Flowmeters

Routine maintenance is necessary to ensure optimal performance and longevity of panel type flowmeters. Here are some key maintenance tips:

Regular Inspections

Conduct periodic inspections of the flowmeter to check for leaks, wear, and damage. Early detection of issues can prevent costly downtimes.

Cleaning Procedures

Contaminants and buildup can affect flowmeter performance. Regular cleaning according to manufacturer recommendations will help maintain accuracy.

Software Updates

If the flowmeter incorporates digital technology, ensure that software updates are applied regularly to enhance performance and security.

Challenges in Gas Flow Measurement and How to Overcome Them

While panel type flowmeters offer many advantages, they also face challenges that can impact measurement accuracy. Understanding these challenges and their solutions is essential for effective gas flow measurement.

Temperature and Pressure Variations

Gas flow can be significantly affected by changes in temperature and pressure. Utilizing flowmeters with built-in compensation features can help mitigate these effects.

Corrosive and Hazardous Gases

Measuring corrosive gases poses risks to both equipment and personnel. Selecting flowmeters made of compatible materials can enhance durability and safety.

Installation Errors

Improper installation can lead to measurement errors. Following installation guidelines and engaging qualified personnel can help ensure accurate setups.

Future Trends in Flow Measurement Technology

The field of flow measurement is continuously evolving, driven by advancements in technology and industry demands. Some future trends include:

Integration of IoT and Smart Technologies

The integration of Internet of Things (IoT) technologies in flow measurement systems will allow for real-time monitoring and data analytics, enhancing operational efficiency.

Advanced Sensor Technologies

Emerging sensor technologies, including laser-based and fiber-optic sensors, promise to further improve measurement accuracy and reduce maintenance needs.

Increased Focus on Sustainability

As industries become more environmentally conscious, there will be a greater emphasis on flow measurement solutions that minimize waste and energy consumption.

Frequently Asked Questions

1. What is the primary advantage of panel type flowmeters over traditional flowmeters?

Panel type flowmeters offer enhanced accuracy, a user-friendly interface, and versatility in application, making them a preferred choice for many industries.

2. How often should panel type flowmeters be calibrated?

Calibration frequency depends on the specific application and operating conditions, but it is generally recommended to calibrate at least once a year or whenever process changes occur.

3. Can panel type flowmeters measure corrosive gases?

Yes, panel type flowmeters can be designed with materials that resist corrosion, making them suitable for measuring various corrosive gases.

4. What maintenance practices should be performed on panel type flowmeters?

Regular inspections, cleaning procedures, and software updates are key maintenance practices that ensure optimal performance and longevity of panel type flowmeters.

5. How do temperature and pressure changes affect gas flow measurement accuracy?

Temperature and pressure variations can cause significant changes in gas density, impacting flow measurement. Flowmeters with built-in compensation features can help mitigate these effects.

Conclusion

Panel type flowmeters play a crucial role in enhancing gas flow measurement accuracy across various industries. With their advanced sensing technologies, user-friendly interfaces, and versatility, these devices deliver reliable data essential for efficient operations. By understanding their functionality, advantages, and maintenance practices, businesses can effectively leverage panel type flowmeters to optimize their processes and ensure compliance with regulatory standards. As technology continues to evolve, these flowmeters will undoubtedly remain integral to the future of gas measurement solutions.

Flowmeter-panel type

RELATED NEWS

Understanding Vorex Flow Meters: Innovations in Fluid Measurement

2025-05-01

Top Benefits of Using Acrylic Flow Meters in Industrial Applications

2025-04-24

Understanding Durable Plastic Tube Type Flowmeters: Key Insights and Applications

2025-04-17